Materials Testing

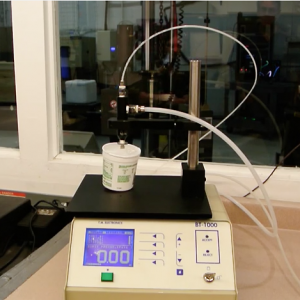

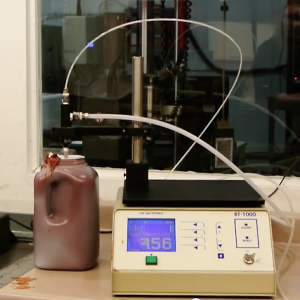

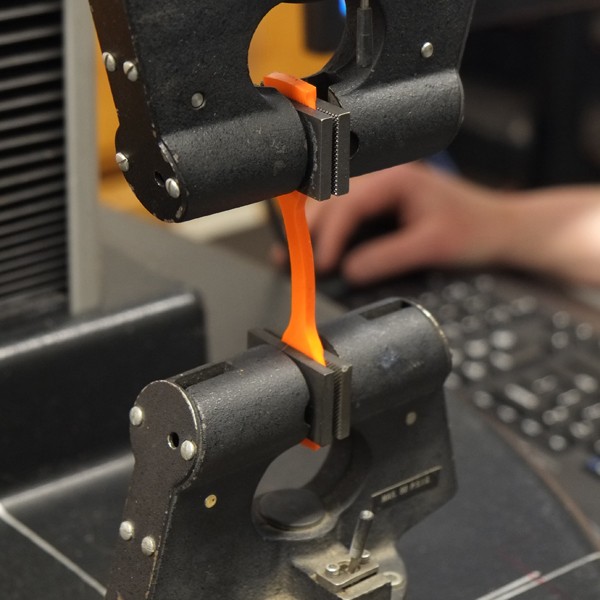

In addition to testing the strength and integrity of packaging, Advanced Packaging Technology Laboratories also tests the component materials that make-up the packaging. The physical and chemical properties and barrier capabilities are important characteristics to aid in the design process.

Although suppliers provide documentation supporting the physical and chemical properties of the materials, there are circumstances that often require additional material and component testing. Our team of engineers and technicians are well-versed in the most current testing standards and can help package designers translate the test results into package design options.

For example, plastic film supporting documentation might include:

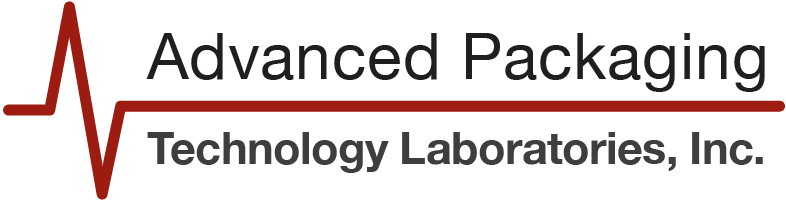

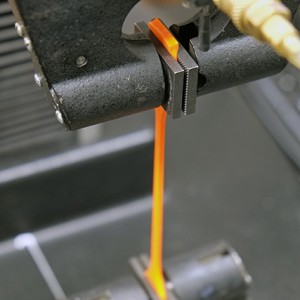

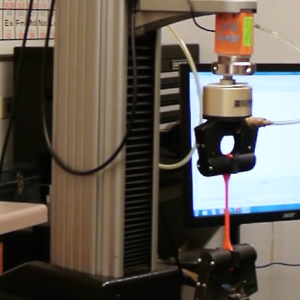

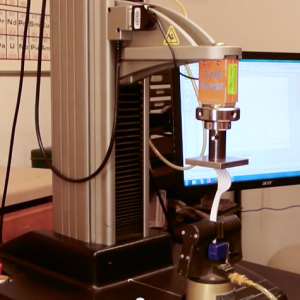

- Tensile strength (MD and CD)

- Elongation

- Elastic modulus

- Surface energy,

- Thickness

- Moisture vapor transmission rate,

- Oxygen transmission rate,

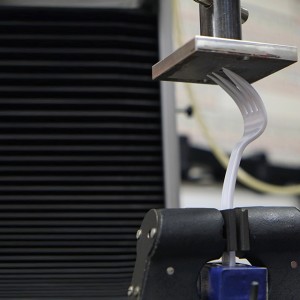

- Heat seal strength, heat sealing conditions

Tensile Testing – Can your packaging material protect your package contents?

Request a Quote