Will Your Packaging Pass the Heat & Humidity Test?

Over the last 30 plus years we have seen hot days getting hotter, rainfall getting heavier and hurricanes getting stronger. We have experienced an increasing number of days of extreme heat and humidity. Over the past summer alone, the United States experienced two deadly rounds of heat and humidity prompting heat advisories and warnings. All 50 states have experienced record breaking heat making everyone vulnerable to the impacts associated with climate change.

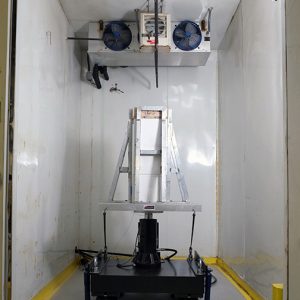

Increased exposure to heat changes the way companies’ package and ship products. Vigilance is the key to surviving for companies who rely on positive package performance. Advanced Packaging Technology Laboratories (APTL) help their customers navigate the packaging process with state-of-the-art environmental and walk-in temperature chambers that simulate the most severe weather conditions.

APTL is equipped to perform:

– Package / pallet load temperature / humidity conditioning before conducting ISTA / ASTM package test programs

– Temperature / humidity conditioning before conducting compression tests

– Accelerated aging of corrugated, paper and plastic materials with temperature / humidity

– Material testing at completion of conditioning program

– Temperature decay of insulated medical packages

– Vibration testing at temperature conditions

– Life cycle testing of a customer’s product at temperature / humidity conditions

– Long -term temperature / humidity tests to evaluate products

– Temperature / humidity cycling tests

– Water spray / rain tests

– Temperature conditions ranging from -90°F (-68°C) to +356°F (+180°C)

– Thermocouple system to monitor multiple temperature points