Growing To Fit Our Customers Needs

Advanced Packaging Technology Laboratories Unveiled Its Remolded Testing Facility

Wheeling, IL, November 8, 2021 – Advanced Packaging Technology Laboratories (APTL), a leader in the ISTA/ASTM package testing industry, has unveiled its newly remolded ISTA and Materials Lab after securing additional space adjacent to the existing facility.

The addition dramatically increases the testing capacity of the site. This investment marks a significant expansion, with the facility’s total footprint to roughly 16,000 square feet.

“We are very proud of the work our team does at this facility and the fact that we continue to grow and innovate,” said Monica White, Laboratory Director. “This newly remodeled space will allow us to turn projects around much more quickly and still deliver upon the quality testing services for which we are known.”

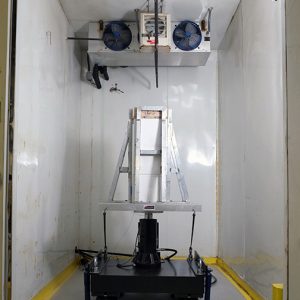

APTL has added a new Cincinnati sub-zero walk-in environmental chamber, a MTS vibration machine, and two new drop testers. In addition, to updating both existing vibration machines and the horizontal impact machine.

APTL opened in 1993 and has continued to expand throughout the years. This current expansion marks the 4th significant expansion to meet the growing needs of APTL customers.